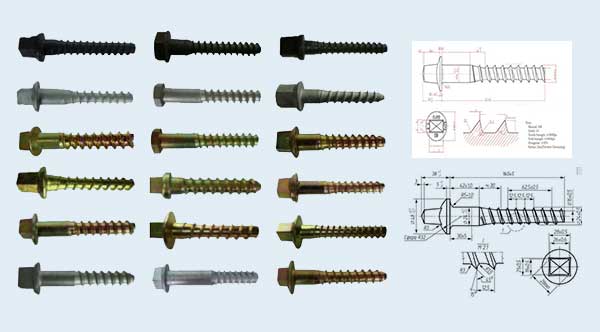

As a key component of railway fasteners, rail screw Spike play an irreplaceable role in securing rails to sleepers, ensuring the stability, safety, and durability of railway tracks. Whether for heavy-haul freight lines, high-speed passenger railways, or urban light rail systems, high-quality rail screw spikes are the cornerstone of maintaining track geometry and reducing operational risks.

Rail screw spike are threaded fasteners used to connect rails, sleeper pads, and sleepers (wood, concrete, or composite materials) in railway track systems. Unlike traditional cut screws, their threaded structure provides stronger clamping force and is easier to install/remove, thus finding widespread use in modern railway construction and maintenance.

The main geometric parameters of threaded track spikes are as follows:

(I) Major Diameter/Outer Diameter (D, d): The diameter of the imaginary cylinder where the crest of the external thread or the root of the internal thread coincides. The major diameter basically represents the nominal diameter of the thread.

(II) Pitch Diameter (D2, d2): D2 = d2 = D(d) - 2 x 3H/8, where H is the height of the original triangle: H = (√3 / 2)P = 0.866025P (60° angle); H = 0.960491P (55° angle)

(III) Minor Diameter/Root Diameter (D1, d1): The diameter of the imaginary cylinder where the crest of the external thread or the crest of the internal thread coincides.

(IV) Pitch (P): The axial distance between two corresponding points on the pitch diameter line of adjacent threads, or the distance between adjacent thread crests or two adjacent thread valleys. In the imperial system, the pitch is indicated by the number of teeth per inch (25.4 mm).

(V) Thread angle (α/2): The angle between the tooth flank and the perpendicular line to the thread axis. The thread angle for ordinary threads is 60°/2, and for Webster's thread (BSW) threads it is 55°/2. Generally, the bevel angle of a wood screw is 60°, and the tail angle is 60°.

(VI) Thread engagement length: The length of the portion of two mating threads that engage along the thread axis.

Main geometric parameters of threaded spikes (self-tapping, self-drilling):

(I) Major diameter/outer diameter (d1):

The diameter of the imaginary cylinder where the thread crests coincide. The major diameter basically represents the nominal diameter of the thread.

(II) Minor diameter/root diameter (d2):

The diameter of the imaginary cylinder where the thread roots coincide.

(III) Pitch (p):

The axial distance between two corresponding points on the pitch diameter of adjacent teeth. In imperial units, thread pitch is indicated by the number of threads per inch (25.4 mm).

Self-drilling screws: Self-drilling screws come in two types: CSD (machine thread) and BSD (self-tapping AB thread). Their thread pitch or number of threads can be referenced from machine screws (CSD thread) and self-tapping screws (BSD thread), respectively.

(IV) Thread Angle and Tail Tip Angle:

The thread angle is the angle between the thread flanks, and the tail tip angle is the pointed angle at the end of the thread.

1. Self-tapping thread:

Thread angle is 60°, tail tip angle is 45°±5°.

2. Wallboard nail:

Thread angle is 60° (can also be produced according to customer requirements, such as 45°±5°), tail tip angle is 25°±3°.

3. Chip board screws:

Thread angle is 40°±3°, tail tip angle is 25°±3° or 34°±3° (customer special requirements). 4. Self-drilling screws: The bevel angle is 60°±5°. Different models of chucks are selected for different product specifications. The main geometric parameters of the chuck are the chuck diameter and the extension.

V. Threaded rod tooth profiles

(I) Mechanical threads

1. Ordinary threads: The tooth profile is triangular, used for connecting or fastening parts. Ordinary threads are divided into coarse and fine threads according to the pitch. Fine threads have higher connection strength.

2. Transmission threads: Tooth profiles include trapezoidal, rectangular, sawtooth, and triangular.

3. Sealing threads: Used for sealing connections, mainly pipe threads, tapered threads, and tapered pipe threads.

(II) Self-tapping threads

Tooth profiles: Currently, self-tapping screw tooth profiles include A, AB, B, BT, etc. The bevel angle of wall panel screws is 60 degrees (can also be produced according to customer requirements, such as 45°±5°), and the tip angle is 25°±3°. The clamping nail and the toothed angle are 40 degrees. The self-drilling screw has a toothed angle of 60 degrees ± 5. Different models of self-drilling pins are selected for the tail of products of different specifications.

Key Advantages of Our Rail Screw Spikes

Our rail screw spikes stand out in the market thanks to rigorous quality control, advanced manufacturing processes, and customer-centric design. Here are their core competitive advantages:

1. High-Strength Material Selection for Durability

We use high-grade alloy steel (such as 45# steel, 35CrMo steel) and stainless steel as raw materials, which undergo quenching and tempering heat treatment to achieve a tensile strength of ≥8.8 (up to 12.9 for special requirements). This ensures the spikes can withstand heavy loads (clamping forces up to 200kN) without deformation or breakage, making them suitable for high-speed railways (350km/h) and heavy-haul freight lines (100t axle load).

For coastal or high-humidity areas, we offer hot-dip galvanizing or Dacromet coating treatments, which improve corrosion resistance by 3-5 times compared to ordinary painting, and extend the service life to 15-20 years.

2. Precision Thread Design for Strong Clamping Force

Our rail spikes feature a fine-tooth design (2.0-2.5mm pitch) and are machined using a roll forming process. Compared to machining, this increases thread strength by 20%, while ensuring uniform thread pitch and a tight fit with the nut or sleeper threaded sleeve. A unique anti-loosening structure (optional nylon insert or washer) effectively prevents thread loosening caused by long-term train vibration, reducing maintenance frequency by 40%.

3. Universal Compatibility and Easy Installation

Our rail spikes are designed according to international standards (e.g., DIN 571, ISO 898-1, AREMA) and are compatible with various types of sleepers (concrete, wood, composite materials) and rails (UIC 54, UIC 60, BS 113A). Standardized dimensions (length: 80mm-200mm, diameter: M16-M24) and matching installation tools (electric wrench, torque wrench) enable rapid installation, reducing construction time by 30% compared to traditional nails.

4. Rigorous Quality Inspection, Meeting International Standards

Each batch of rail screw spike undergoes rigorous quality inspection, including:

- Material Inspection: Chemical composition is analyzed using a spectrometer to ensure compliance with standards.

- Mechanical Performance Testing: Tensile testing, hardness testing (Rockwell hardness HRC 28-32), and impact testing to verify strength and toughness.

- Corrosion Resistance Testing: Salt spray testing (500 hours for galvanized products) to ensure corrosion resistance.

- Dimensional Inspection: Thread accuracy and overall dimensions are checked using a coordinate measuring machine to ensure interchangeability.

Our products are ISO 9001 quality management system certified, CE certified (for the European market), and AAR certified (for the North American rail market), ensuring compliance with global rail industry requirements.

WhatsApp

WhatsApp WeChat

WeChat